The Apprentice

ap∙pren∙tice

“one who is learning by practical experience under skilled workers”

The system of apprenticeships was first developed in the Middle Ages, and came to be supervised by craft guilds and town governments. Master Craftsmen employed apprentices who were an inexpensive form of labour, in exchange for providing food, lodging and formal training. Apprentices usually began at 10-15 years of age and would live in the Master Craftsman’s household until the completion of their contract. Most apprentices aspired to becoming Master Craftsmen, and were required to serve seven years before being allowed to practice a trade themselves.

The mainstay of training in industry has been through the apprenticeship system. The highest levels of apprentice recruitment were between the mid 1960’s and 1970’s, but even then only 15% of school leavers took up apprenticeships. Traditional apprenticeships reached their lowest point in the late 1970’s.

In 1986 NVQ’s were introduced, in an attempt to revitalise vocational training, but still by 1990, apprenticeships took up only two-thirds of 1% of total employment. In 1994 the Government introduced Modern Apprenticeships which are an excellent way of gaining qualifications and workplace experience.

Although Modern Apprenticeships are ideal in many sectors, it is the Traditional Apprenticeship route which is used at Platts & Nisbett. There are great similarities with the methods used by the old Master Craftsmen. Since the formation of the Company in 1977 we have always trained our own apprentices, in an effort to avoid skills gaps and shortages in the future.

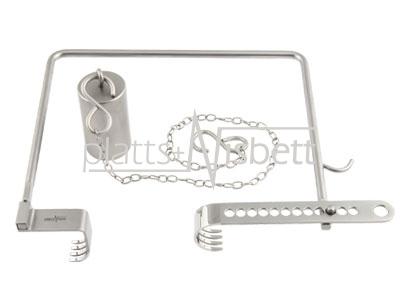

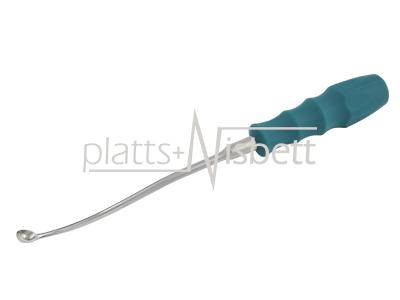

All our apprentices are assigned a mentor, and receive specialist one to one training from surgical instrument makers with over thirty years experience. They learn how to use traditional tools and manufacturing methods to produce surgical instruments of only the highest standard. During their apprenticeship, which lasts between five and six years, it is instilled into them that quality is everything. Although it is a time consuming and labour intensive process, the time spent teaching them is an investment for the future. As apprentices progress, they are gradually assigned jobs of a higher difficulty. Only when competent can the apprentice move on to the next level, and work with slightly less supervision. Once they are qualified and begin to gain experience they then take on the additional responsibility of teaching an apprentice themselves. This continuous cycle is vital in order to protect a trade which would otherwise disappear.

We have recently dedicated a workshop specifically for our apprentices and their mentors, which is already proving to be a great success. It provides an excellent teaching environment, where apprentices learn not only the vital skills, but how to work as part of a team.

We look forward to producing the next generation of skilled surgical instrument makers who can produce items worthy of carrying the Platts & Nisbett name.